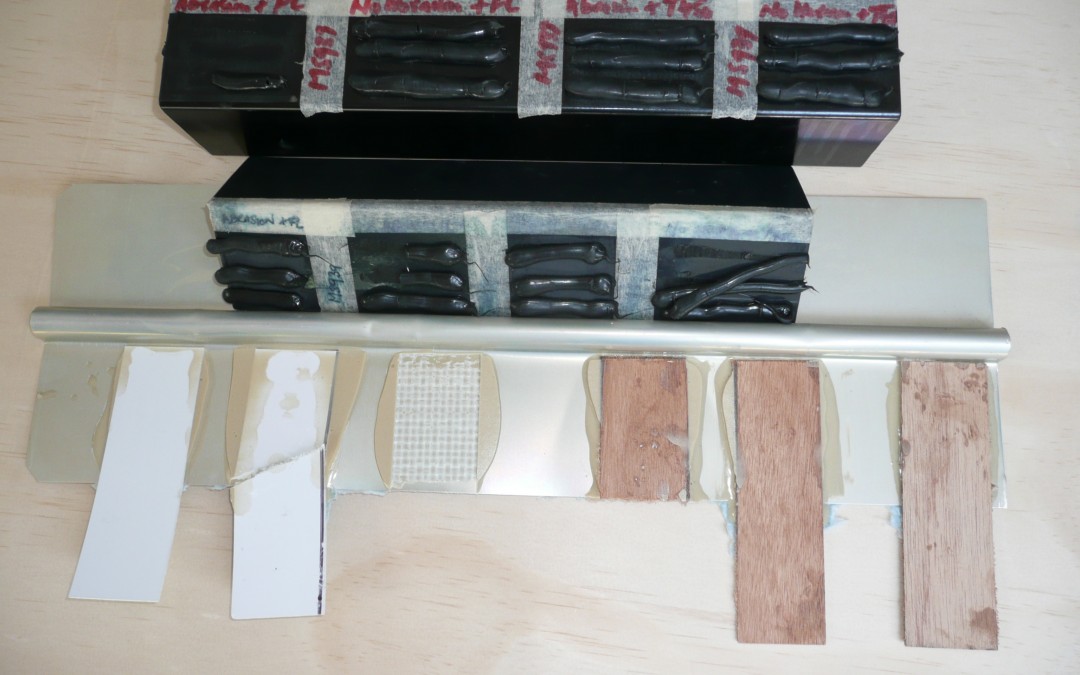

Adhesive Labortory Testing

Not leaving anything to chance Wildplanet engaged one of the worlds leading

adhesive companies to conduct extensive trials in their Australian laboratories

Initial adhesion tests were carried out at room temperatures and the second

stage climate testing were placed into a chamber that operates at 65 degrees

Celsius and at 85% humidity.

Every few days the test sections were placed into a freezer to create a

thermal shock before then being placed back into the chamber.

This process was untaken over many weeks before the final evaluation.

This testing provided an excellent in-site into the overall performance of the

bond between the adhesive and the selected substrate after having the

climate exposure.

To obtain maximum adhesion the adhesive bead shape and thickness is

important.

The photograph shows the various substrates that were tested.

Timber bonded aluminium.

Fibreglass sheet bonded to aluminium

Powder coat & two pack epoxy paint finished steel adhesion tests.

Owners of a Wildplanet Off Road Expedition vehicles can be assured that the

most technological advanced adhesives have been selected for the specific

application.